I've actually poured the concrete and have the track laid out on my "Not-quite-a-wye" that I asked for input on in another thread. I decided to flip the orientation, as it eliminated a reverse curve from the inner loop of track.

Here's the current layout:

![Image]()

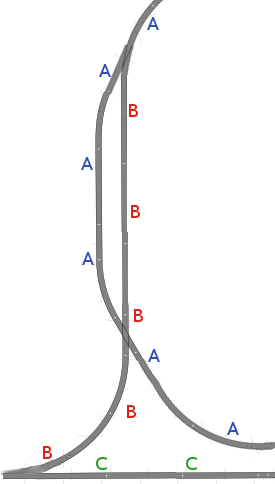

The track labeled with a green "C" on the very bottom is the main-line loop of my layout. The track labeled with the blue "A" is an inner loop that goes past my industries. This will allow me to run two trains simultaneously without having to do collision detection, detect occupied blocks, etc. In front of my station and service yard are a set of crossovers that would allow a train to switch from one loop to the other, if that were needed/desired.

The Not-quite-a-wye (labeled with the red "B") will allow me to reverse trains without resorting to the "hand of god" method--and I just think it looks neat

Anyway, in tracing this out for DCC, I believe that the entire section labeled "B" needs to be isolated from the rest of the layout and attached to a DDC reversing module. Before I start putting on track joiners, I thought I'd get some input from the experts here. If more (or less) needs to be isolated, please let me know!

Thanks,

Dan

Here's the current layout:

The track labeled with a green "C" on the very bottom is the main-line loop of my layout. The track labeled with the blue "A" is an inner loop that goes past my industries. This will allow me to run two trains simultaneously without having to do collision detection, detect occupied blocks, etc. In front of my station and service yard are a set of crossovers that would allow a train to switch from one loop to the other, if that were needed/desired.

The Not-quite-a-wye (labeled with the red "B") will allow me to reverse trains without resorting to the "hand of god" method--and I just think it looks neat

Anyway, in tracing this out for DCC, I believe that the entire section labeled "B" needs to be isolated from the rest of the layout and attached to a DDC reversing module. Before I start putting on track joiners, I thought I'd get some input from the experts here. If more (or less) needs to be isolated, please let me know!

Thanks,

Dan