Hi guys,

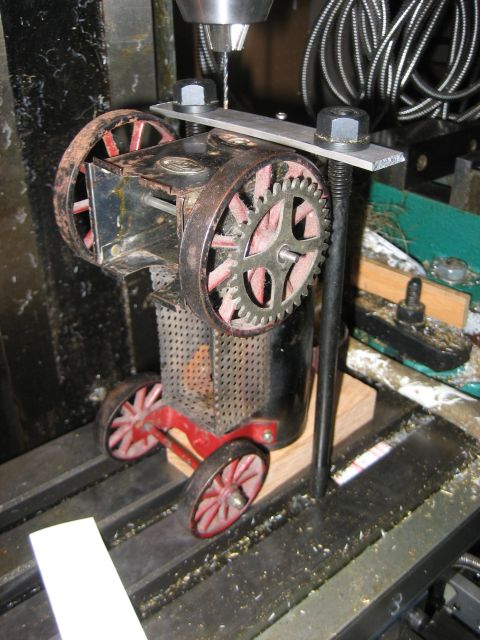

you might have wondered (or not even noticed - depending on your preferences) where my pestering reports about the progress of the Guinness brewery loco have gone. I took a break from this project and started with the restoration of a delightful little steam toy for a friend of mine. It is a Doll portable - basically a steam engine on wheels with some means of self-propelling; not yet as sophisticated as the later steam tractor. This little engine will later be used either as a load or for powering a business on Richards layout. As received it was in a pretty sorry state: All of the valve gear was missing, the fittings frozen solid and no burner. I intended to leave as much patina as possible, but get it back to live. First task was to remove water gauge, safety valve and whistle. After I broke one of the screws for the water gauge, I decided to drill all screws out and replace them with modern ones. The obsolete M2.3 thread luckily has the same pitch as M2.5, so I could just go through the old threads with a tap. But first I had to remove the broken screw:

![Image]()

The drive chain was also missing, but one ordered from SDP was a perfect fit:

![Image]()

I studied some of the valve gears on Doll engines pictured on the WWW, but none of them would fit the remnants of this one. From the holes in the steam chest I could design the valve and the throw of the eccentric. It turned out that the slip eccentric and the throw are identical with the modern Wilesco steam engines. The eccentics were machined from bronze, while the valve connecting rod was "stolen" from a Wilesco engine (leftover from our donkey project). I also opted for the rollers, which show up on some photos of Doll engines and reduce friction between valve and hold-down spring. Here pictures of the new parts:

![Image]()

![Image]()

Dennis donated a surplus wooden handle for the whistle:

![Image]()

and later he brought out his fancy safety valve tester to set the safety valve:

![Image]()

The portable runs very well on air with about 10 PSi, so there is hope it will soon steam again. Next steps are nickel plating the new parts and starting with the burner (alcohol with 2..3 wicks). But now back to the Guinness

![Image]()

.

Regards

you might have wondered (or not even noticed - depending on your preferences) where my pestering reports about the progress of the Guinness brewery loco have gone. I took a break from this project and started with the restoration of a delightful little steam toy for a friend of mine. It is a Doll portable - basically a steam engine on wheels with some means of self-propelling; not yet as sophisticated as the later steam tractor. This little engine will later be used either as a load or for powering a business on Richards layout. As received it was in a pretty sorry state: All of the valve gear was missing, the fittings frozen solid and no burner. I intended to leave as much patina as possible, but get it back to live. First task was to remove water gauge, safety valve and whistle. After I broke one of the screws for the water gauge, I decided to drill all screws out and replace them with modern ones. The obsolete M2.3 thread luckily has the same pitch as M2.5, so I could just go through the old threads with a tap. But first I had to remove the broken screw:

The drive chain was also missing, but one ordered from SDP was a perfect fit:

I studied some of the valve gears on Doll engines pictured on the WWW, but none of them would fit the remnants of this one. From the holes in the steam chest I could design the valve and the throw of the eccentric. It turned out that the slip eccentric and the throw are identical with the modern Wilesco steam engines. The eccentics were machined from bronze, while the valve connecting rod was "stolen" from a Wilesco engine (leftover from our donkey project). I also opted for the rollers, which show up on some photos of Doll engines and reduce friction between valve and hold-down spring. Here pictures of the new parts:

Dennis donated a surplus wooden handle for the whistle:

and later he brought out his fancy safety valve tester to set the safety valve:

The portable runs very well on air with about 10 PSi, so there is hope it will soon steam again. Next steps are nickel plating the new parts and starting with the burner (alcohol with 2..3 wicks). But now back to the Guinness

Regards