mallard claims the fame to the worlds fastest steam loco, at 126 MPH, but few know that PRR e7s 7002 acheived the speed of 127 MPH. why has history not been corrected?

Mallard is not the fastest!

21 - 40 of 81 Posts

Joined

·

1,180 Posts

if you couple, say 1361(we're pretending shes restored people ), to the end of the amtak acela and she has steam and you crack open the throttle, and the acela was going 130 mph, would she be the worlds fastest?

), to the end of the amtak acela and she has steam and you crack open the throttle, and the acela was going 130 mph, would she be the worlds fastest?

Joined

·

1,194 Posts

Why settle for the Acela? The TGV could get her up to 200mph.

Joined

·

3,001 Posts

Folks;

I'd like to add some information regarding the "hammer blow" (dynamic augment). People seem to think that it had a negative effect on the rail.

Back in 1981/82, as the technical writer for the NW Computer Services Department, I was assigned the task of creating a data collection procedures manual for NW's Plasser track geometry car. I had to work closely with the systems analyst on this project and also make several trips on the track geometry car itself. The problem at the time was that the relatively new 100 ton capacity coal hoppers were beating up the track, which was mostly 132 pound to the yard rail.

When the data got analyzed, an interesting result appeared. Track that was put down during the steam era was resisting the onslaught of the 100 ton hoppers. The analysts decided that the dynamic augment from all those Ys, Js, As, and Ks had acted like a blacksmith tempering a piece of iron or steel. The rail head was "work hardened" and could survive the pounding from the 100 ton hopper cars. Of course, N&W steam locomotives were very well balanced, and perhaps that helped. But dynamic augment is not necessarily a negative effect.

Now back to the regular thread,

David Meashey

I'd like to add some information regarding the "hammer blow" (dynamic augment). People seem to think that it had a negative effect on the rail.

Back in 1981/82, as the technical writer for the NW Computer Services Department, I was assigned the task of creating a data collection procedures manual for NW's Plasser track geometry car. I had to work closely with the systems analyst on this project and also make several trips on the track geometry car itself. The problem at the time was that the relatively new 100 ton capacity coal hoppers were beating up the track, which was mostly 132 pound to the yard rail.

When the data got analyzed, an interesting result appeared. Track that was put down during the steam era was resisting the onslaught of the 100 ton hoppers. The analysts decided that the dynamic augment from all those Ys, Js, As, and Ks had acted like a blacksmith tempering a piece of iron or steel. The rail head was "work hardened" and could survive the pounding from the 100 ton hopper cars. Of course, N&W steam locomotives were very well balanced, and perhaps that helped. But dynamic augment is not necessarily a negative effect.

Now back to the regular thread,

David Meashey

Joined

·

2,271 Posts

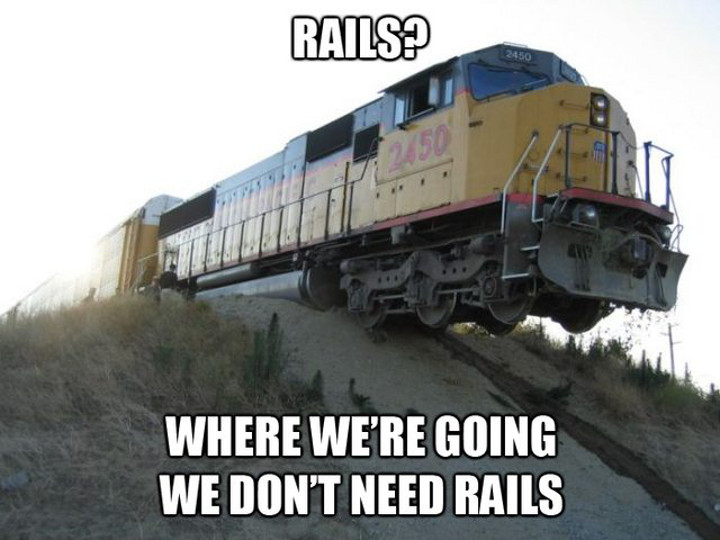

Could the term 'banking' have a different meaning in the USA than the UK?guys this is the solution

![Image]()

I'm not familiar with above technique of railroad operations.

Andrew

Joined

·

941 Posts

That's how they illegally change the engine oil when nobody's looking. After it's all drained out, the just reverse it back on the track!

Joined

·

2,271 Posts

That wouldn't work because it would be too hard to find the sump plug in all that dirt.That's how they illegally change the engine oil when nobody's looking. After it's all drained out, the just reverse it back on the track!

Andrew

Joined

·

1,180 Posts

the shop crew got word that the inspection pit was out of service, so they had to improvise

Joined

·

1,180 Posts

the virginian didnt want to let union pacific have all the great ideas, so they invented door-to-door service

![Image]()

dave, that may work with wooden ties, but concrete is a whole different story(i think concrete ties are the ugliest and worst thing ),

),

dave, that may work with wooden ties, but concrete is a whole different story(i think concrete ties are the ugliest and worst thing

Joined

·

1,500 Posts

Nate

That logo belongs NOT to our beloved Virginian Railway of the US, but to Victorian Railways of AUSTRALIA. Oooooops!

That logo belongs NOT to our beloved Virginian Railway of the US, but to Victorian Railways of AUSTRALIA. Oooooops!

Joined

·

2,271 Posts

Yep, its a Victorian Railways B class or S class.

My first HO engine.

![Image]()

Andrew

My first HO engine.

Andrew

Joined

·

1,180 Posts

oops..

could N&W 611 possibly beat her?

could N&W 611 possibly beat her?

Joined

·

1,563 Posts

Actually straight track isn't really great for high speeds because the wheels tend to oscillate from one flange to another on, straight track taking up the side play between the gauge and the flanges. This creates a long sinusoidal movement between the left flange and the right one over a distance, I don't know the exact English term for this in French it's "mouvement de lacet". It ends up deforming the track.

Actually Linwood Moody claimed that some SR&RL engines used to clip along at 60 Mph, pretty good for two foot gauge!

Reg is right the Milwaukee had some of the best steam runs ever just before WW2. His explanation for why the railroads in the US didn't advertise their speed exploits is very interesting. I had never understood why the Pennsy didn't exploit the obviously frequent runs at high speeds performed by the T1. Now I am beginning to understand why.

Actually the problems linked with high speeds were most often not what we think they are (IE: the track) more like the signaling system and the block length, the system for setting off the RR crossing gates, and most of all the breaking system for the trains. One T1 fireman said that once when they were trying to make up the schedule they went so fast that they passed the crossing gates before they closed, it freaked them out.

Actually Linwood Moody claimed that some SR&RL engines used to clip along at 60 Mph, pretty good for two foot gauge!

Reg is right the Milwaukee had some of the best steam runs ever just before WW2. His explanation for why the railroads in the US didn't advertise their speed exploits is very interesting. I had never understood why the Pennsy didn't exploit the obviously frequent runs at high speeds performed by the T1. Now I am beginning to understand why.

Actually the problems linked with high speeds were most often not what we think they are (IE: the track) more like the signaling system and the block length, the system for setting off the RR crossing gates, and most of all the breaking system for the trains. One T1 fireman said that once when they were trying to make up the schedule they went so fast that they passed the crossing gates before they closed, it freaked them out.

Joined

·

8,406 Posts

Re: attaching an engine to a TGV.

There is a documented and you-tubed incident where Blue Peter, an A2, was allowed to spin its drivers on wet rail until the valve gear disintegrated. They reckoned it was spinning at the equivalent of 165 mph.

So Acela - maybe. TGV -no.

There is a documented and you-tubed incident where Blue Peter, an A2, was allowed to spin its drivers on wet rail until the valve gear disintegrated. They reckoned it was spinning at the equivalent of 165 mph.

So Acela - maybe. TGV -no.

Joined

·

1,500 Posts

Peter T

And the driver should have been executed on the spot for both incompetence and iron "horse" abuse. As I recall he was a BR employee with not a great deal of steam experience.

And the driver should have been executed on the spot for both incompetence and iron "horse" abuse. As I recall he was a BR employee with not a great deal of steam experience.

Joined

·

2,271 Posts

On her home track or host's track?oops..

could N&W 611 possibly beat her?

Andrew

Joined

·

1,007 Posts

It was not entirely his fault. The throttle/reverser design played also a role. The engineer was also severely injured while trying to stop the beast.Peter T

And the driver should have been executed on the spot for both incompetence and iron "horse" abuse. As I recall he was a BR employee with not a great deal of steam experience.

http://www.liveleak.com/view?i=1f8_1387134457

About the world record for steam locos:

The Germans attained the record in 1936 at 200.4km/h (124.5mph). Of course the Brits had to top that and ran the Mallard at 125.88 mph,returning the world record to England. However this was achieved on a downhill grade and after the run the Mallard was damaged.

Regards

Joined

·

3,537 Posts

Sorry Henner, but reading that link shows that it was entirely his fault.It was not entirely his fault. The throttle/reverser design played also a role.

Okay, perhaps the fact that he did not know the locomotive helped.

As far as I know, that class of loco never seemed to have any problems when in regular service.

And what does "When the driver attempted to wind the reversing gear back into mid-position to halt the slip, the force of the boiler spun it into full-forward position," mean?

They didn't have power reversers, so why couldn't he get it to mid position.

All very sad really, as all it needs is for ONLY trained crews to run preserved locos.

All the best,

David Leech, Delta, Canada

Joined

·

2,271 Posts

I read that the crew overfilled it with water which caused the regulator to prime. That initiated a series of mishaps afterwards for the driver who was unfamiliar with that particular locomotive along with the speculation of him not wanting to stall the locomotive up a grade.

I don't quite understand how a screw could be driven in reverse by the boiler either but I'm not so familiar with all the big stuff.

Andrew

I don't quite understand how a screw could be driven in reverse by the boiler either but I'm not so familiar with all the big stuff.

Andrew

Joined

·

1,180 Posts

i aslo read that ALL running gear components/fixtures had to be rebuilt or replaced. all of the drivers needed new tires pressed on, and one or two drivers had to be replaced(new ones were cast). i once saw an old film and i think it was at the worlds fair years ago where the rails were purposely greased and a dreyfuss hudson was allowed to spin in place

jim, an execution wont teach him a lesson, but having both arms broken will!

i find it kinda funny how far this thread has wanderd

jim, an execution wont teach him a lesson, but having both arms broken will!

i find it kinda funny how far this thread has wanderd

Joined

·

1,180 Posts

i wouldnt trust leting our beloved J out of our sight. maybe somewhere on the northeast corridor.. no , we learned that the hard way with that dealdy crash..maybe on some old PRR trackage? that what the t-1's ran on..On her home track or host's track?

Andrew

or better yet, the D&SNG high line

21 - 40 of 81 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 460K

- members

- 32K

- Since

- 2007

A forum community dedicated to G scale model train owners and enthusiasts. Come join the discussion about collections, displays, models, styles, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

Greg Elmassian

81 Replies

boilingwater

25 Replies

Pete Thornton

23 Replies