Since some of you fellows have shown such an interest in old farm tractors for your layouts. I dug up some pix and catalog cuts of a visually interesting, yet relatively simple one. It's of about WWI vintage (built from 1910-27), so it will work on most layouts, either new, in use, derelict in a hedgerow, or on a flatcar headed for the scrapyard.

I bring you the Flour City tractor, made by the Kinnard & Sons Mfg. Co. of Minneapolis, Minn.

Flour City tractors were made in 5 models in 4 sizes: I've included some dims from the catalog to help you scale the rest.....

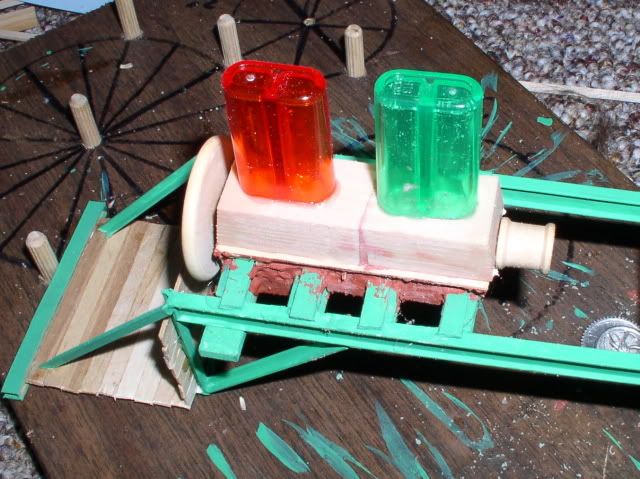

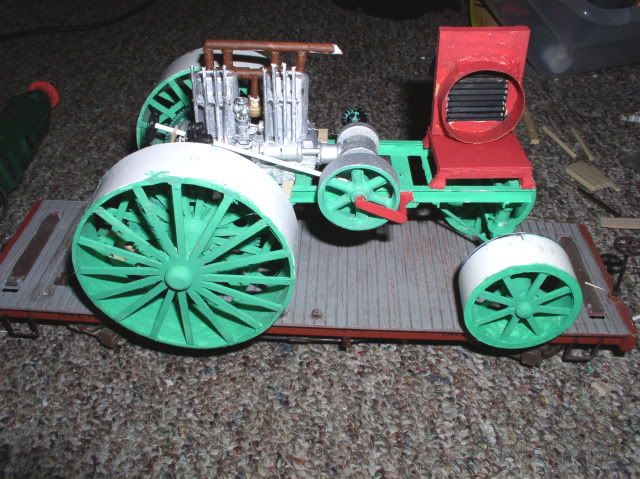

The 12-24 Junior-

![Image]()

![Image]()

![Image]()

Belt Pullley..................26 x 71/2 in

Front Wheels.............................. 38 x 5 in.

Traction Wheels...........60 in., Face (R-12 in., L-14 in.)

Length.........................................152 in.

Width..........................................84 in.

Wheel Base..................................92 in.

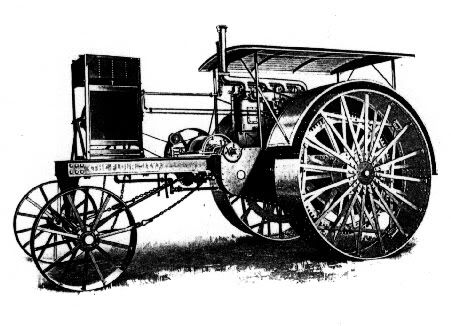

The 20-35 -

![Image]()

Belt Pulley .............................................................................. 26 x 8

*Traction Wheels .................................................................... 6 ft. x 18 in.

Front Wheels .......................................................................... 42 x 8

Wheel Base ............................................................................ 9 ft.

Width Outside Trac. Wheels ................................................... 80 in.

The 30-50 -

![Image]()

Belt Pulley .............................................................................. 32 x 9

*Traction Wheels ................................................................... 7 f t. x 24 in

Front Wheels ......................................................................... 48 x 9

Wheel Base ............................................................................ 11 ft.

Width Outside Trac. Wheels ................................................... 96 in.

The 40-70 -

![Image]()

![Image]()

Belt Pulley ............................................................................... 34 x 10

*Traction Wheels .................................................................... 8 ft. x 24 in.

Front Wheels .......................................................................... 48 x 10

Wheel Base ............................................................................ 13 ft. 6 in.

Width Outside Trac. Wheels ................................................... 111 in.

And the 40-70 special road tractor -

![Image]()

![Image]()

![Image]()

Okay, so now you're all saying 'simple?' It should be if you break it into steps. To help with that, here are some original 1919 catalog cuts to get us started:

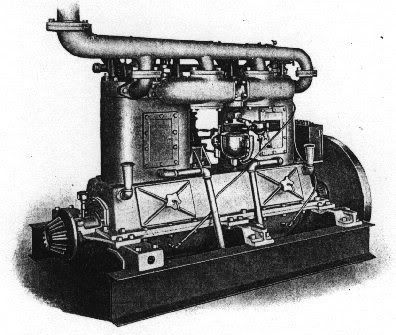

engine bed with crank -

![Image]()

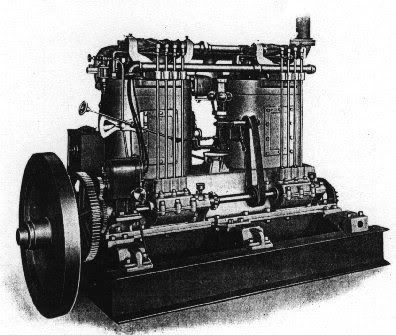

engine cylinders and heads -

![Image]()

Engine assembly -

![Image]()

![Image]()

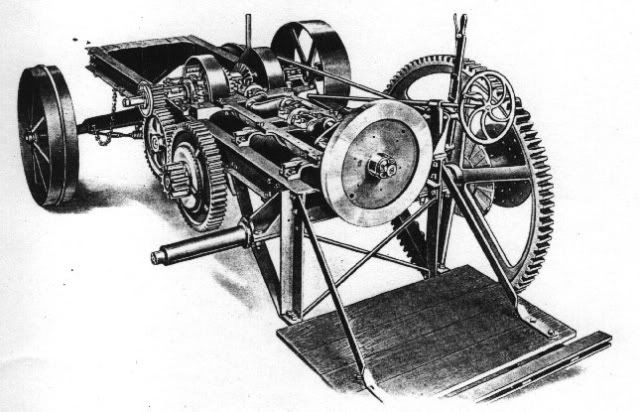

Gearbox and frame layout -

![Image]()

![Image]()

Rear wheel with bull gear -

![Image]()

Operator's platform -

![Image]()

And some pix to show scale -

12-24 plowing

![Image]()

30-50 threshing

![Image]()

40-70 threshing

![Image]()

40-70 with steam traction plow

![Image]()

40-70 special with grader

![Image]()

anybody up to the challenge? I have some ideas on how to build it. But feel free to share yours....

I bring you the Flour City tractor, made by the Kinnard & Sons Mfg. Co. of Minneapolis, Minn.

Flour City tractors were made in 5 models in 4 sizes: I've included some dims from the catalog to help you scale the rest.....

The 12-24 Junior-

Belt Pullley..................26 x 71/2 in

Front Wheels.............................. 38 x 5 in.

Traction Wheels...........60 in., Face (R-12 in., L-14 in.)

Length.........................................152 in.

Width..........................................84 in.

Wheel Base..................................92 in.

The 20-35 -

Belt Pulley .............................................................................. 26 x 8

*Traction Wheels .................................................................... 6 ft. x 18 in.

Front Wheels .......................................................................... 42 x 8

Wheel Base ............................................................................ 9 ft.

Width Outside Trac. Wheels ................................................... 80 in.

The 30-50 -

Belt Pulley .............................................................................. 32 x 9

*Traction Wheels ................................................................... 7 f t. x 24 in

Front Wheels ......................................................................... 48 x 9

Wheel Base ............................................................................ 11 ft.

Width Outside Trac. Wheels ................................................... 96 in.

The 40-70 -

Belt Pulley ............................................................................... 34 x 10

*Traction Wheels .................................................................... 8 ft. x 24 in.

Front Wheels .......................................................................... 48 x 10

Wheel Base ............................................................................ 13 ft. 6 in.

Width Outside Trac. Wheels ................................................... 111 in.

And the 40-70 special road tractor -

Okay, so now you're all saying 'simple?' It should be if you break it into steps. To help with that, here are some original 1919 catalog cuts to get us started:

engine bed with crank -

engine cylinders and heads -

Engine assembly -

Gearbox and frame layout -

Rear wheel with bull gear -

Operator's platform -

And some pix to show scale -

12-24 plowing

30-50 threshing

40-70 threshing

40-70 with steam traction plow

40-70 special with grader

anybody up to the challenge? I have some ideas on how to build it. But feel free to share yours....