I have found wear on a couple of my high use locomotive axles to the point where the axles needed replacing. I would love to avoid that in the future.

I have been using 3in1 oil. it tends to collect dirt which compounds the wear. Is there a better material?

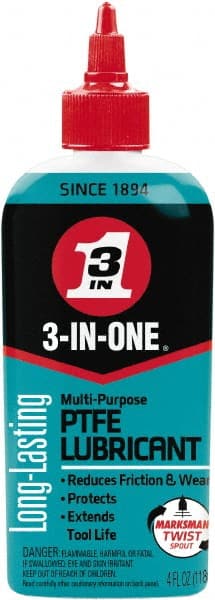

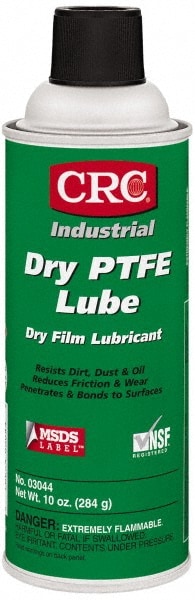

how about teflon dry lube? such as one with the 3in1 name on it? any one have Spencerian with this type of stuff?

![Image]()

or

![Image]()

I have been using 3in1 oil. it tends to collect dirt which compounds the wear. Is there a better material?

how about teflon dry lube? such as one with the 3in1 name on it? any one have Spencerian with this type of stuff?