The definitive answer: (okay, I'm being obnoxiously egotisitcal with that statement... but, I bet it got your attention ;-) )

Anyways, my thoughts:

The Bachmann Shay (and Climax and heisler) and the Aristo or USA Geeps (GP's or "General Purpose") are, for all practicality, the same engine. In each case, the locomotive is a solid frame supported by two pivoting, self-contained power assemblies. Those assemblies are all two-axle trucks. Both axles are geared to a single motor through worm and pinion gears.

This means you need to consider the aspects of other issues. Bachmann's trucks have a history of issues, however by most reports they seem to have solved the issues in the later revisions. I have an early edition, which reduces my ability to state facts here. However, one thing to consider... there is now a 3-truck shay available (a premium price though). And prototypically, there were 4-truck shays. This would effectively increase your pulling power. However, there is the maintenance issue.... The shays and other logging engines have metal rods which need periodic lubing, much like the original prototypes. Is this an issue for you?

The USA trucks have the split axle issue. Are you willing to deal with this? The good thing with this engine is the increased tractive effort created by the use of traction tires. However, this is also a bad issue, and might be at the heart to the split axle(though I don't know this to be true)... When overloaded, the traction tyre will prevent slipping. This means the locomotive will stall out. The motor will stop turning, yet the torque created by the magnetic fields in the motor will still be present. This WILL put strain on the gears. If the traction tyre is on one wheel on an axle, and not on the other, it could create uneven torque conditions within the axle. IF you can figure out the limits of the engine and ensure you don't exceed its mechanical limits, the USA traction tyre equipped truck will serve you well. To overcome the reduced power pickup created by the traction tyre, they are equipped with sliders like the LGB products. As traction tyres age, they dry out and become brittle. Eventually they will tear apart and come out, leaving a heavy groove in the surface of the wheel, necessitating the locomotive's removal from service.

The CURRENT Aristo truck is equipped with ball bearings within the drive train. This will allow it to handle a great deal of additional weight to act as ballast to increase its tractive effort. The bad: Aristo's quality control issues are well known, however they always backup their products. If there is an issue, they will work with you to solve it. Aristo has consistently stated that they do no like the sliders' toy-like appearance, and consequently designed a modular ball-bearing equipped gearbox to allow them to skip the traction tyres and use pure adhesive weight for traction. The advantage here is that unlike traction tyres, which adhere to the rail through friction, the steel Aristo wheels adhere to the rail through gravity. When the load being pulled by the engine exceeds the adhesive weight of the engine, the engine will stall. Unlike the USA diesels, the wheels are free to slip on the rail surface. From the time the locomotive stalls until the wheels break free of the rail, there will be increased stress on the gearing.

Once the wheels break free and begin to spin, the stress will be reduced. As long as you don't weigh now the engine with an excessive amount of weight, the traction motor's torque will always exceed the adhesive weight of the engine. There is a down side to a stall with the wheels spinning. Like any metal on metal without lubrication, there will be a tendency for the metal to be destroyed. This will usually end up with depressions ground into the rail... definitely in aluminum rail, most likely in brass. I don't know which is harder... the steel drive wheels or the stainless steel rails. I believe Aristo said the wheels were harder, but I don't know if anyone who has confirmed this. The decision to be made is which is easier to deal with? a locomotive out of service until its traction power systems are repaired, or like the real railroads, cutting out a bad section or rail and replacing it?

Your decision should probably be based on two factors:

1) Do you want steam or diesel?

Steam? then your choice is:

Bachmann: 2-truck shay, heisler, climax or three-truck shay

Hartland's Big John, (which could be bashed to look more like a climax or Hiesler, check the model making forum)

Diesel? Here you have a much wider choice:

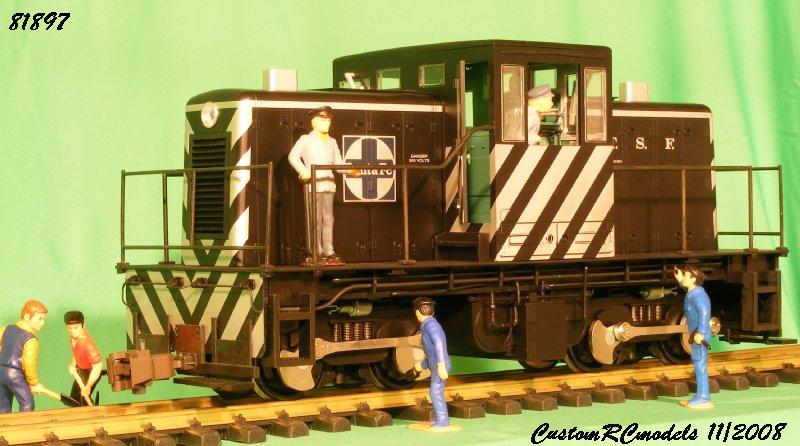

Aristocraft: FA-1 & FB-1 (individually or sets), RS-3, GP-40, or the RS-3-based Centercab

Bachmann: You might still be able to find their GE Centercab switcher

USA Trains: GP-7/9, GP-30, GP-38-2, Alco S4, GE 44-ton Centercab, NW-2 (calf&cow sets available)

In both steam and diesel outlines, you could also consider two (or three) doubleheaded little critter engines. Aristo has their little RS-1/3 or their 0-4-0 Steam switcher. Bachmann has a variety of x-4-x based steam engines you could consider. Hartland has their little Macks in both diesel & electric version. USA has their critter based on the NW-2 (an NW-1/2?) but I see its not listed on teh site anymore. There are a host of smaller LGB engines that go on ebay at any given time. Two of these could help as well. If you were to go with teh critter option, I'd highly recommend adding "heavy" wires to make them electrically one engine, basically giving you steam Geep.

Your other question was about mismatched speeds... I've given this a lot of thought lately. If you ever see pictures/video of the NS yard crews working in Enola or Altoona (both PA yards), they are often using a remote controlled GP-38 coupled to an MP15DC, which is the modern equivalent to the old NW-2 or Alco S4. They don't match speeds either.

Here is my thought on the issue: every time we pull a train, we have speed-mismatched equipment: The engine is always faster than a freight car (unless the brakes are released and the car is rolling down hill) Test the engines you want to lash together. if they are fairly close, it shouldn't matter which order you put them in the consist. If you are running a VERY light train, or there is a large speed difference, I'd put the faster one in the front. This is because it be no different than putting a large train behind it that forces it to slow down.

However, I would NOT try to run a shay with a Geep.

Oh, that brings up one thought I wanted to caution you about. The Shay is a good puller because of its gearing. Changing the gearing increases the torque available to the wheels, but reduces its top speed. If you have big hills and kids who like to run at "light speed", this could be a benefit... the shay's gearing will make it impossible for it to go careening out of control and wrecking at the bottom of the grade (or on any curves on the grade). However, it's top speed might be too slow for your preferences. You might want to consider this factor in making your decision. The shay, hiesler and climax all run significantly slower than any other engine on the market.

Good luck on your choice, let us know. I personally am planning on double headed LGB 2-4-0's for the branchline on my railroad while 4-6-2, 2-8-2 and other big steam ply the mainline.