On the straight and flat my Bachmann 4-6-0 pulls fine, but with the slightest increase (grade, tight curve, etc.) motor revs and it doesn't move. I have been into the drive train and I can't be sure, but my best guess is that the final drive gear is slipping on its shaft. It is pressed on a weakly knurled shaft, but it likely spun once so is prone to now. I was thinking of coming into the shaft/gear joint from both sides with super glue and hope enough wicks between the two to secure the gear. Thought I would check hear first to see if someone else had this same issue and found a better solution. Thanks for any help on this. Jim

Drive gear slipping on my 1:24 Bachmann 4-6-0

yellow_cad

1 - 20 of 36 Posts

Joined

·

520 Posts

On the straight and flat my Bachmann 4-6-0 pulls fine, but with the slightest increase (grade, tight curve, etc.) motor revs and it doesn't move. I have been into the drive train and I can't be sure, but my best guess is that the final drive gear is slipping on its shaft. It is pressed on a weakly knurled shaft, but it likely spun once so is prone to now. I was thinking of coming into the shaft/gear joint from both sides with super glue and hope enough wicks between the two to secure the gear. Thought I would check hear first to see if someone else had this same issue and found a better solution. Thanks for any help on this. Jim

Jim, Bachmann.com, in their parts section offers just the replacement gear or what still looks like a plastic gear pressed on to the axle. If it is slipping it may also be cracked. Let us know if the adhesive fix works.

Joined

·

4,268 Posts

If not cracked then try to pin it as well as gluing.

Joined

·

520 Posts

I am having a problem finding the drivetrain parts for the 4-6-0 on the Bachmann site.Jim, Bachmann.com, in their parts section offers just the replacement gear or what still looks like a plastic gear pressed on to the axle. If it is slipping it may also be cracked. Let us know if the adhesive fix works.

Could just post the link, but there are other things on their site you may find interesting. I also suggest you join the Forum, very knowledgeable folks there and quick to respond, that is where I am learning.

1: Bachmann.com

2: Parts Service and Info

3: Order Parts, (with the loco pic)

4: upper left drop down menu pic. Large Scale Parts

5: scroll down till you come to the loco you want to look for parts.

I found what you are looking for under. ANNIVERSARY then FRAME & WHEELS you will get an exploded view of the assembly, the parts are numbered.

The parts people are very helpful if you are still having problems. Direct #. 267 297 2494

I must say, looks more difficult to work on than the 2-8-0.

Also, the locos I saw the axles w gears were for the 4-4-0 and 2-6-0.

1: Bachmann.com

2: Parts Service and Info

3: Order Parts, (with the loco pic)

4: upper left drop down menu pic. Large Scale Parts

5: scroll down till you come to the loco you want to look for parts.

I found what you are looking for under. ANNIVERSARY then FRAME & WHEELS you will get an exploded view of the assembly, the parts are numbered.

The parts people are very helpful if you are still having problems. Direct #. 267 297 2494

I must say, looks more difficult to work on than the 2-8-0.

Also, the locos I saw the axles w gears were for the 4-4-0 and 2-6-0.

Joined

·

8,406 Posts

I for one never encountered a slipping gear on an 4-6-0, though I'm sure it has happened.

I do not think your super-glue idea will work. Apart from anything else, that's a 'shear' joint which acc is notoriously bad at gluing. You really need a pin or screw on to a flat spot on the axle. I have managed sometimes to get a collar next to a gear and then bolt to gear to the collar. The collar has a setscrew to tighten it onto the axle.

![Image]()

But no gears, either for the Anniversary or 'standard' 4-6-0. Usually Bachmann sells a motor and gearbox combination. I didn't see one of them either! Aha. Found the gearbox: under "4-6-0 Standard-Detail Parts" for $36. [At that price you could buy a junk one and use it for parts!]several pages of parts that are available,

I do not think your super-glue idea will work. Apart from anything else, that's a 'shear' joint which acc is notoriously bad at gluing. You really need a pin or screw on to a flat spot on the axle. I have managed sometimes to get a collar next to a gear and then bolt to gear to the collar. The collar has a setscrew to tighten it onto the axle.

Joined

·

520 Posts

My final drive gear that is mounted on the shaft of the drive wheels is cracked at its boss. I am not sure how the wheels are attached to the axle so I haven't forced anything in that regard. Without removing the wheels, I can't get to it to pin or sleeve. Would anyone know if the shaft is chromed thereby making it more difficult to drill? If I do just glue it, I would clean it up real good with alcohol. Anyone have an idea of what glue would work best for attaching nylon gear to steel (maybe chromed) shaft, super glue, 5 minute epoxy, Gorilla Glue, etc? Thanks for any thoughts. Jim

Joined

·

24,522 Posts

Cracked gear, replace, no glue will work, nylon not fun. Join the Bachmann forum and read the sticky at the top of the forum and then ask for help if you still need it.

Greg

Greg

Joined

·

520 Posts

I called Bachmann and they don't sell the drive gear. Their only remedy for that model is to buy a complete new chassis for $90. Worse yet the replacement chassis also has nylon gears and the metal gear chassis will not be available for about one year. Can anyone tell me how these wheels are attached to the axle so I can remove them to get at the gear?

Pete, I found an old MLS posting of yours from 08 where you inquired about removing the wheels, did you ever come up with a solution?

Thank You,

Thank You,

Joined

·

8,406 Posts

Excuse me, but I found a complete gearbox for $36 - see post #6. Maybe they didn't understand which version you have.I called Bachmann and they don't sell the drive gear.

Are you sure this is a 4-6-0? How old is it? There are 5 or 6 generations, and the latest/decent ones have a bump under the axle. Also take a look at this:

Big Haulers Tips

It is not chromed and not stainless. The wheels have a nylon insert to isolate them from the axle. If you have the right tools, it can be filed or drilled.Would anyone know if the shaft is chromed thereby making it more difficult to drill?

They are actually dead simple. In typical Bachmann fashion, they have a screw in the center to hold the wheel onto the axle. The screw is hidden behind the wheel insert.Can anyone tell me how these wheels are attached to the axle so I can remove them to get at the gear?

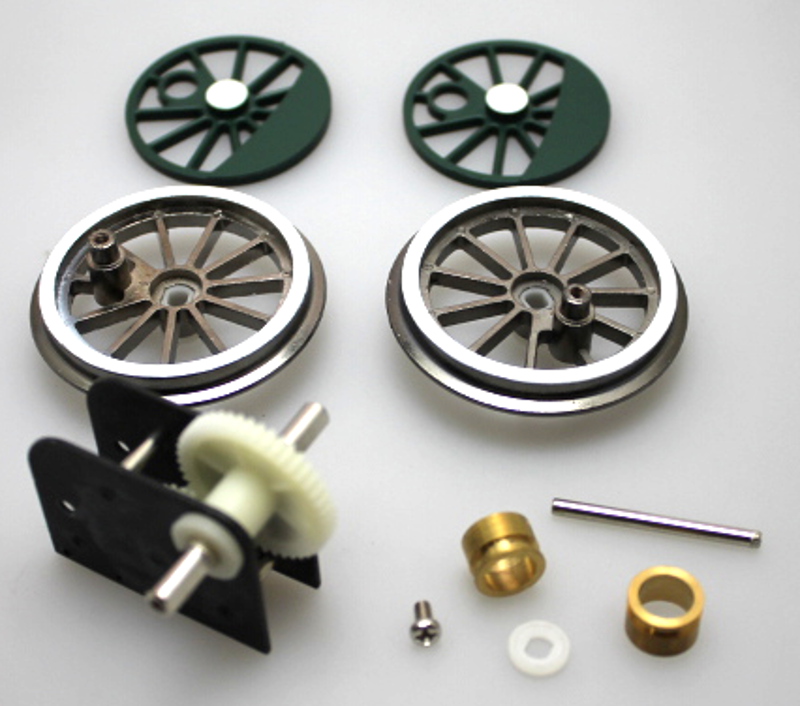

To remove the wheel insert (see pic below from Bachmann's gearbox listing,)

Gearbox & Wheel Set Assembly - Black (Large 4-6-0) [0AY01-00J05-MTG48-B] - $35.79 : Bachmann Trains Online Store!

you look behind the wheel for the balance weight. As you can see below, the balance weight is not molded into the wheel, so it is visible between the spokes from the inside. Take a small screwdriver and press it out from the back!

This gearbox may not fit your motor and the gear may not fit your gearbox! But if you take off the wheels you should be able to push the axle out of the gear and free it all up.

Post a picture or two as you do it.

Joined

·

520 Posts

Here is a photo of my final drive gear mounted on the shaft. I am not sure how to remove these wheels from the axle so I can attach a sleeve that will hold the gear fast on the shaft. The gear is cracked and Bachmann says they only supply the entire chassis as a replacement and it is $89. If I could remove the wheels, then I could jerry rig some fix.

Attachments

-

243.6 KB Views: 231

Pete, you last pic explained why I couldn't see a seam in the little hub at the center of the wheels on mine, never considered that the whole wheel cover could be removed. Not sure which version I have, unmarked with the 'sound' system in the tender.

Joined

·

8,406 Posts

Yellow_cad (don't you have a more friendly name?),I am not sure how to remove these wheels from the axle

Weren't my instructions above any use? See the green arrow on your pic, below? Insert small screwdriver or pointed implement and push the wheel insert out.

The green arrow is at the side opposite the crankpin so you will see the balance weight between the spokes. This is what it looks like from the back - see the balance weight?

And yes, your gear is cracked and you will need to replace it or the whole gearbox.

Joined

·

520 Posts

I believe you are saying to use the balance weight to push the wheel off of the axle so the axle must be square on the ends and a press fit in the wheels. It looks like in the photo that one wheel has a male attachment and the other a female attachment. I'm not sure if this is an allusion and really both wheels have a female attachment. And, finally my last reservation is whether these wheels will go back together and be completely firm and rigid as they are now since this is essential to correct operation.

By the way, if I get the wheels off, I plan to make a shaft collar that I can attach to the gear and anchor to the shaft to stop all slippage of the gear on the shaft since they don't sell the gear and I don't want to buy the complete chassis.

By the way, if I get the wheels off, I plan to make a shaft collar that I can attach to the gear and anchor to the shaft to stop all slippage of the gear on the shaft since they don't sell the gear and I don't want to buy the complete chassis.

If I may, you appear to be very lucky that the crack is only at the bottom of the gear, at this time. If the crack works it's way to the top, the teeth will separate and no longer mesh properly. I don't know if this will work for this case, but years ago when we had a cracked head, would drill a hole at the end of the crack, that would stop it from growing. After that would tap and insert threaded rod and grind off excess. In this case just drilling the hole would do.

Joined

·

520 Posts

That's a good point and I could drill that hole parallel to the axle, but it all depends on whether I can successfully remove and later reattach the wheels. I I can't remove the wheels, then I intend to get a split collar shaft with the axle ID and turn into that a shoulder that will grip the entire gear boss on one side and hopefully this will take the strain off of the crack.

Joined

·

520 Posts

Sorry, I I can't remove the wheels should read If I can't remove the wheels.

Joined

·

8,406 Posts

If you look at the photos I posted, especially the ones from the Bachmann website, you will notice the wheel insert is separate from the wheel. Back in post #11, I said:I believe you are saying to use the balance weight to push the wheel off of the axle

So you pop the wheel insert out of the wheel, and unscrew the center screw. The wheels have a nylon sleeve and the axles have a flat on both sides at the end so the wheels stay quartered correctly (= one wheel at 90 deg from the other.)In typical Bachmann fashion, they have a screw in the center to hold the wheel onto the axle.

It's an illusion. Those are the center blind drivers, not the wheels on the drive axle. Take a close look at this picture:It looks like in the photo that one wheel has a male attachment and the other a female attachment. I'm not sure if this is an allusion and really both wheels have a female attachment.

It looks to me that you have the (very) old style wiper contacts, shown on George Schreyer's site (you did at least look closely at his pictures, I hope?) Those locos didn't have the thick boss in the center of the wheels that is shown above, but otherwise they are similar.

I'll repeat what I said earlier - you need a new gear or a new chassis. Once they start to crack, the plastic is brittle and will continue to break. Bachmann occasionally sells the chassis 1/2 price, or you should find one on eBay for less than $50.

Joined

·

520 Posts

Thanks Pete. I will check for the half price sale. One last question on disassembling the wheels from the shaft. I tried to remove some sort of plug to get to the screws, but it looks to be glued or molded in. Do I need to destroy the material covering the screw (white in color) in order to loosen the screw and take off the wheel?

Also, this exploded view that I believe is my model doesn't show any screws.

![Image]()

Also, this exploded view that I believe is my model doesn't show any screws.

1 - 20 of 36 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 460K

- members

- 32K

- Since

- 2007

A forum community dedicated to G scale model train owners and enthusiasts. Come join the discussion about collections, displays, models, styles, scales, reviews, accessories, classifieds, and more!

Top Contributors this Month

View All

Greg Elmassian

81 Replies

boilingwater

25 Replies

Pete Thornton

23 Replies